By Morten Rossé, Yoni Shiran, and Martin Stuchtey from the McKinsey Center for Business and Environment

The circular economy is getting considerable attention. A conference on the subject in June at the EU Commission in Brussels attracted more than 700 people, and Britain’s Guardian newspaper has a blog devoted to the subject. In our day-to-day work with clients, we are finding that more and more people, on every rung of the business ladder, are intrigued with the idea of using resources more productively, creatively—and profitably. They get the idea that going circular can help them do so.

This is all to the good—and not nearly enough. Companies need to turn the theory of circularity into business practice. But they have concerns. “What will circularity mean to the bottom line?” we are asked. “Where is the competitive advantage for us?” “How will my customers benefit?” These are all fair questions.

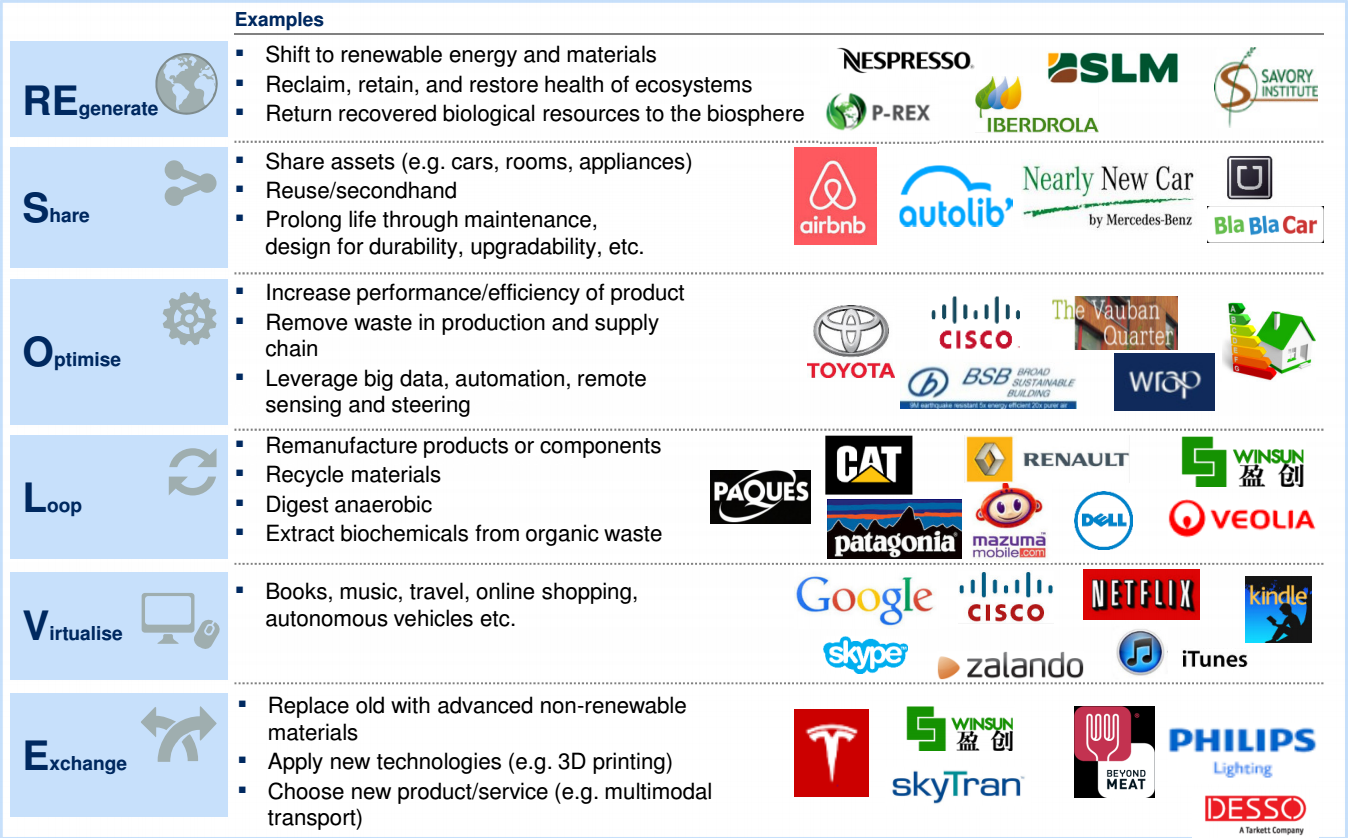

To help answer them, McKinsey has created a framework known as ReSOLVE, which comprises six ways to bring circular principles to life: ReGenerate, Share, Optimise, Loop, Virtualise and Exchange. Based on this framework, McKinsey has developed ReSOLVER, a tool that has proved capable of helping companies figure out which actions to take and also to calculate their likely costs and benefits.

A car manufacturer considering some circular options, for example, might want to know the implications for OEMs (revenues, profit, balance sheet); consumers (total cost of ownership); and society (emissions, resource use, and ancillary benefits such as congestion and safety). ReSOLVER uses company-specific information to calculate each of these outputs under different business models. This broader perspective, which takes the entire value chain into account, allows different business models to be compared and thus provides a basis for figuring out where circular opportunities best fit. Not every option can be used in every circumstance; in fact, it would be unusual for that to happen.

With that in mind, let’s say a carmaker—call it WheelsCo—wants to explore some circular options. One business model it might consider is to move from products to services, selling kilometers rather than cars. WheelsCo would maintain possession of the fleet; consumers would access cars without owning them. Using the ReSOLVE framework, how might this play out? [i]

- Share: We estimate that under this model, the average car would be driven as much as 10 times as far (188,000 kilometers a year, versus today’s average of 18,000) ; it would also service three people, twice as many as now. That improves the productivity of each vehicle 20 times. Moreover, WheelsCo would have an incentive to build cars that last longer, reducing manufacturing costs per kilometer.

- Optimise: Because WheelsCo owns the vehicle, it maintains them much better than the average driver, prolonging their useful life. In addition, WheelsCo can strike better deals for things like insurance and financing, passing on lower costs to consumers while increasing profits.

- Loop: Vehicle ownership enables WheelsCo to remanufacture components and recycle materials when the car comes to the end of its (extended) life, reducing procurement, assembly, and transportation costs.

- Virtualise: The car industry is facing the new reality that many driving events are substituted by virtual exchange. In today’s model, this will shrink the revenue base. In the far future, WheelsCo might consider ways to benefit from the hours given back to consumers. Offering customers to take access capacity into sharing schemes could be a way to take advantage of peak availabilities through virtualisation.

- Exchange: Today, electric vehicles (EVs) are more expensive than conventional ones, despite having a much lower marginal cost per kilometer. With each car getting driven more, however, the economics of EVs improve markedly. In another example of swapping one technology for a better one, 3D printing uses less energy, and generates less waste than traditional manufacturing.

If WheelsCo did everything right—and of course this is the challenge—we estimate it could over time quadruple its profits, lower costs to consumers by a third, and reduce related GHG emissions by 78 percent.

That’s an intriguing proposition, but WheelsCo will have to change the way it looks at value. Like in the early days of lean manufacturing, it will find that changing the perspective will allow to see waste and to eradicate it. The challenge this time: radical alternatives to the product design, the supply chain and the business model will all have to be considered at the same time. This is not something that companies do often. In fact, frequently the representatives of the different business functions met the first time in our circular labs.

The larger point is this: If circularity is to become mainstream, it needs to be systematic, not feel-good. There needs to be economic value at stake, as much as social values. That means that companies have to be able to identify, quantify, and prioritise strategic circular-economy opportunities. We believe many companies are genuinely curious about the potential of circular principles, but they are daunted by the practicalities and caught between the long- and the short-term. But quick wins are possible. Once that happens, companies are more apt to see that they can create value with little or no new material inputs. Given that many resources are likely to get more uncontrollable in price and availability, that is an attractive business proposition.

[i] REgenerate can be a major source of value in other industries, but is less relevant to this example.

___________

Morten Rossé, Expert Associate Principal, McKinsey Center for Business & Environment

Yoni Shiran, Associate, McKinsey & Co.

Martin Stuchtey, Director, McKinsey Center for Business & Environment