At 2degrees, we have just finished an initial study with Oxford University’s Said Business School looking at our work with Asda-Walmart, Tesco and others. It showed that the European grocery industry alone could save up to $38.3 billion by simply normalizing best practice in energy, waste, and water management. That’s just over 3% of the sales value of the industry—or close to the pre-tax profits of most large food retailers—simply for doing things that have already been proven to work by peers and competitors.

How can this be? Surely food retailers and their supply chains are among the most efficient organizations on the planet. Well, it would seem that applying the lens of sustainability and new forms of collaboration can make them significantly more efficient still.

The Problem with Silos and Supply Chains

The study shows that there are two main causes of this unnecessary wastefulness:

- Silos. Our organizations have become very efficient at achieving short-term goals within their silos, but when a long-term systems perspective is taken, they often look very inefficient.

As a simple example, we recently came across a loose/fresh potato buyer. He typically purchased high-quality potatoes that met a certain standard for shape and size. But that meant leaving up to 30% of any crop to rot in the field, because Mother Nature had not signed up to his definition of “quality.” In the same building—on the same floor in fact—was a colleague buying ready meals that often contained mashed potatoes. You can see where this goes. The company switched to buying the loose potato farmer’s entire crop, and now sells all the small and odd-shaped ones to the ready meal manufacturer. Presto! One third less waste.

We have become organizations of specialists that are very efficient at specific tasks, but the byproduct of specialization is that we have become siloed—we lack real visibility within our supply chains, so we often miss the big picture.

- A transactional and aggressive culture of buying. Selling and buying is an increasingly aggressive and confrontational process. It leaves scars, reduces relationships to transactions, and builds mutual suspicion and paranoia. Sure, it lowers cost in the short term, but it destroys long-term collaborative investment for sustainable supply and affordable prices. As one producer told us, “If they [the retailer] know I am making that investment, they will just take the savings away from me. So why bother?”

Further, by discouraging long-term investment, an aggressive transactional relationship simply pushes costs back down the supply chain, rather than eliminating them. This means that these displaced costs are eventually passed back up in a higher price (or at least the opportunity to reduce prices further is lost).

There are some notable exceptions to aggressive transactional relationships, such as the increasing cooperation between coffee farmers and coffee brands like Nestle. And some retailers are making real efforts to change the way they operate, but they are the exceptions and early on in their journeys. Elsewhere, transaction is king, paranoia normal, and collaboration an afterthought. The result is lost value.

From Siloed Supply Chains to Value Webs

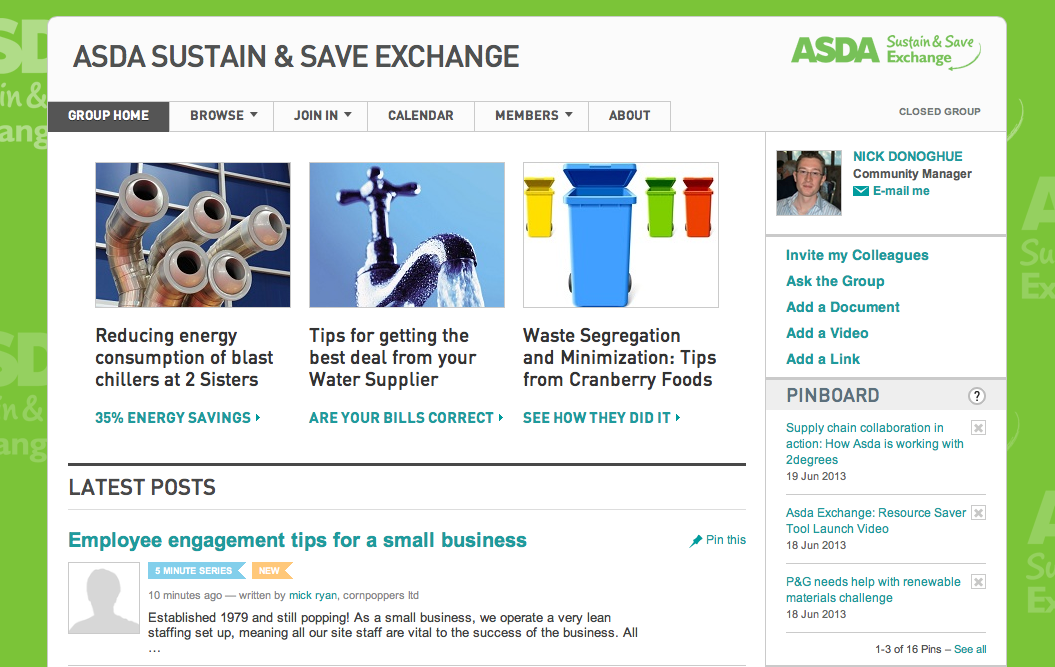

At 2degrees, we are helping Asda-Walmart, Tesco, Kingfisher, GlaxoSmithKline, and others by making it efficient for them to work closely with their suppliers at scale, cut costs and risks, and grow by being more sustainable. (To see the Asda-Walmart Commercial team talking about their Sustain and Save Exchange on 2degrees click here)

At 2degrees, we are helping Asda-Walmart, Tesco, Kingfisher, GlaxoSmithKline, and others by making it efficient for them to work closely with their suppliers at scale, cut costs and risks, and grow by being more sustainable. (To see the Asda-Walmart Commercial team talking about their Sustain and Save Exchange on 2degrees click here)

Using private, secure spaces on our online collaboration platform and a managed program of facilitation, we enable our clients to build new relationships with their suppliers. Just as importantly, we are helping suppliers work with each other in large numbers.

As a result, we are dissolving silos and enabling connections to be made up, down, and across supply chains. At the heart of these new connections are the operational employees: engineers, food technicians, and site and energy managers. These are not the “usual suspects” who frequent conferences, but a normally elusive breed who have the challenges and the “know-how” to drive efficiencies. Making it easy for them to ask each other questions and share insights and best practices–without having to leave their desks–is creating a revolution in business relationships and efficiency. It is a move from a siloed supply chain to a connected value web.

It seems there are four main ways in which knowledge and best-practice sharing—which takes place in these new webs—creates value and drives out costs and environmental impacts:

- Resource efficiency improvements. Suppliers learn from each other on topics from LED lighting to heat capture and reuse. These are generally detailed and technical exchanges between operational managers from different companies, who would never normally talk to one another. As a result of one single conversation thread, a supplier saved over $700,000 by avoiding a mistaken technology purchase that they were about to make.

- Waste to resource. One supplier’s waste could be another’s resource. Taking a systems view and enabling suppliers to talk to one another easily creates often unexpected value. Such has been the case for the mushroom farmer, who no longer pays to have mushroom waste taken away, but instead has it picked up by a cattle farmer as feedstock.

- Capacity optimization. When suppliers talk to each other, the possibility for sharing assets with non-competitors becomes much easier. At 2degrees, we are seeing opportunities for sharing recycling plants, waste-to-energy plants, distribution centers, and long-haul trucks.

- Aggregated buying. Applying a systems perspective to supply chains allows companies to identify opportunities to aggregate demand for technologies and negotiate discounts by buying at scale. We have been helping Tesco do this through Buying Clubs. The first of these Buying Clubs, which focused on LED lighting solutions for distribution centers, secured a 25-30% discount in capital cost for participating suppliers and saves the equivalent of 1,500 homes worth of energy every year.

Trust: The Missing Ingredient

High-level collaboration is not possible without trust. If there is a lack of trust between supplier and buyer, a system must be created to substitute for it. At 2degrees, we have established a set or processes and protocols to assure suppliers that any savings they make from participating in our programs will not be immediately and directly attacked by their customers. These processes involve:

- Suppliers and customers signing up to a set of rules that govern their behavior in 2degrees programs, which are known as Charters

- The involvement of a dedicated 2degrees community management team who act as trusted intermediaries

- Data capture and reporting that keeps supplier identity hidden from over-enthusiastic buyers

These processes enable what we call “Blind Collaboration,” which can make it safe for suppliers to collaborate with their customers and each other. It is possible because of 2degrees’ role as an impartial facilitator. In the absence of real trust between parties, it makes for a pretty good substitute.

The Real Size of the Prize

We have only analyzed the European grocery supply chain so far, but based on an extrapolation from the work we are doing with our clients, there is an enormous win-win-win-win possible for customers, suppliers, consumers, and the environment.

If normalizing best practice in food supply in Europe could generate $38 billion, what are the opportunities in other supply chains, geographies, and industries—especially those that are even more energy-intensive? There are undoubtedly trillions of dollars being wasted; significant unnecessary environmental damage being done; and many opportunities for savings just waiting to be unlocked by the creation of value webs and the facilitation of “blind collaboration.”